Diagnosis Solution

Our solution is a solution that diagnoses, analyzes, and stores defects that can occur during semiconductor manufacturing process in real time, and allows users to directly check

data in real time in a closed FAB environment. Furthermore, we pursue a solution that improves the productivity and competitiveness of our customers by lowering the defect rate

and increasing the semiconductor yield by developing a diagnosis solution based on the data analysis obtained through our solution and predicting the problem occurrence.

Accuracy

freqAI

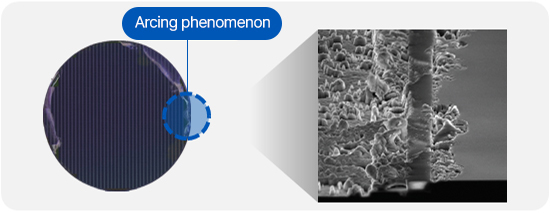

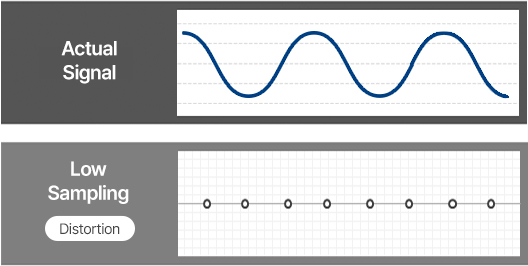

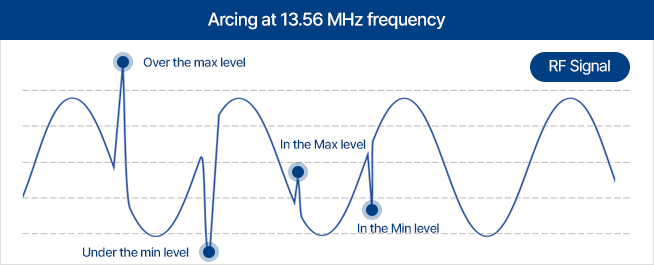

RF sensors are installed on the power transmission line and the frequency signals are analyzed at high speed. The problems of the existing Arcing diagnosis

solution have been improved. WGS’s self-developed ultra-high-speed diagnosis solution.

-

arcing occurs when

arcing occurs when- 1. The circuit on the wafer is damaged

- 2. Rework Process, or

- 3. Loss

-

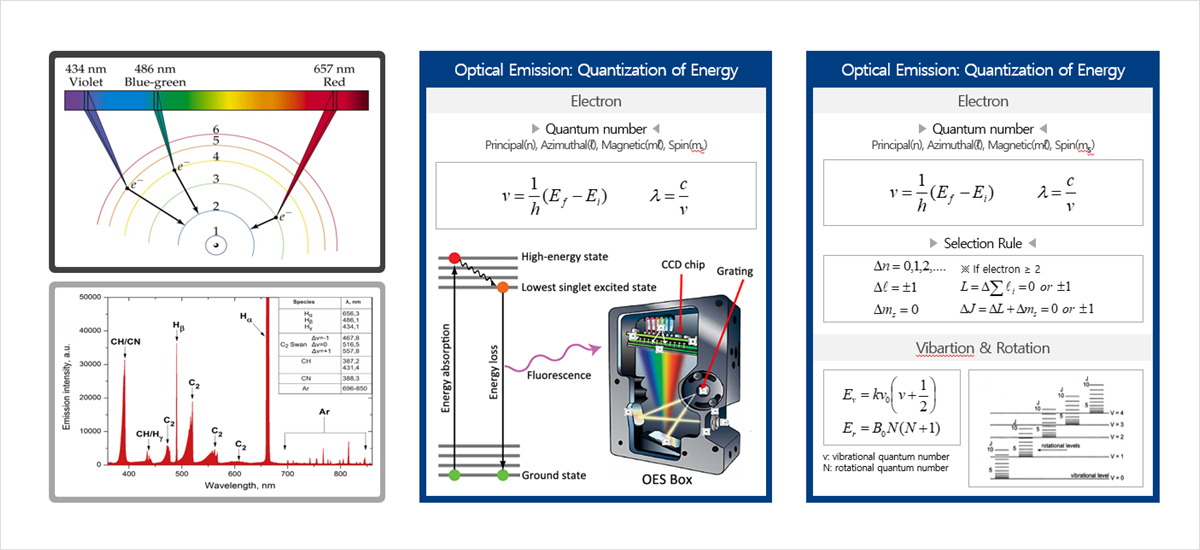

OES System

Optical sensors are installed at the plasma generation location to analyze the plasma formation state. The key to semiconductor yield is “plasma”. Using

OES according to the needs, infinitely expandable diagnosis solution in the process using plasma